Fluorescent synthetic analyzer

Holding Area

Incheon

-

Equipment Description

희토류 컨텀닷 형광체의 실시간 배합 및 평가 모니터링 시스템

UST-KITECH School

Convergence Manufacturing system Engineering

Industrial Materials and Smart Manufacturing Engineering

The Department of Industrial Materials and Smart Manufacturing Engineering fosters excellent researchers in high-tech industrial materials such as electronic materials, light metals, rare earths, ceramics, nanocomposite materials, and inorganic hybrid materials, and advanced manufacturing fields such as semiconductor packaging, high-function thin film, and rare metal recycling and 3D Additive printing. In addition, students in this department study technology that can handle design and validation in virtual space by computational engineering analysis and they learn technologies that apply artificial intelligence technology and Internet of Things technology to manufacturing sites, as it becomes possible to analyze very large engineering models that were not possible in the past due to the rapid development of simulation technology and hardware

Course Objectives

The purpose of this lecture is to provide the students with- the application theory for semiconductor packaging material and electronic materials,- the instruction of the application tools such as device design tools,particularly in view of enlarging the integrated understanding of the students on the materials application.

Course Objectives

Rare earths are being issued due to various industrial and political understanding with nations. To prepare their explosive demand of industry near future, discuss the science within rare earths, and application

Course Objectives

Evaluation and comparing the phase transformations of metals and alloys under solidification and heat treatment conditions in both stable systems and metal stable systems through academic theories and industrial examples.

Course Objectives

Investigation design concepts and synthesis methods on the advanced composite materials which have magneto striction or phase recovering functionalities by emerging fabrication technologies, such as additive manufacturing or phase separation.

Course Objectives

The principle and application of powder fabrication and forming processes for advanced materials and rare metals.

Course Objectives

Understanding the principle and process of organic and inorganic chemical reaction for rare metal elements.

Course Objectives

Engineers learn the theory of fluid mechanics and computational fluid mechanics required in the industrial field, and learn how to simulate real natural phenomena to cultivate the ability to use them for work after graduation

Course Objectives

Understanding and applying the basic concepts and terms of the finite element method widely used in various fields of engineering to direct engineering problems, developing the ability to communicate with engineering analysis using the finite element method, and the ability to analyze the results of the finite element method.

Course Objectives

By understanding the basic concepts and terms of finite element sub-methods widely used in various fields of engineering and applying them to direct engineering problems, developing engineering analysis communication skills, and finite element method result analysis skills.

Course Objectives

Understanding the unique property of each rare earth element with the scientific and industrial R&D and application trend.

Course Objectives

Through the understanding of big data analysis and artificial intelligence, based on the 4th industrial revolution, insights and application capabilities to respond to the field of smart manufacturing processes can be obtained

Course Objectives

Students learn the basic knowledge and elemental process technologies necessary for 3D printing(Addtive Manufacturing), and learn the latest technology trends to cultivate the ability to use them for work after graduation

Course Objectives

Students learn basic theories and techniques for designing optical systems required in the industrial field, and learn various application cases using laser-based measurement and processing technology to cultivate the ability to use them for work after graduation

Details

Position

Head Professor

Major

Industrial Technology

Affiliation

UST-KITECH School

Division

Korea Institute for Rare Metals (KIARM)

bskim15@kitech.re.kr

Homepage

TEL

031-458-5109

Education

1998-02 / Hanyang University / Bachelor's

2000-02 / Hanyang University / Master's

2003-09 / Osaka University / Doctor's

Representative Study

“Thickness control of TiN network in CoCrFeNi matrix composite with tunable microstructure”, Applied Surface Science 543 (30) 148761 (2021)

“Synthesis of one-dimensional neodymium-iron-boron-oxides”, Materials Letters 264 127286 (2020)

"Fine Tuning of Colloidal CdSe Qunautm Dot Photovoltaic Properties by Microfluidic Reactors", Electrochimica Acta 28447 9 (2016)

“Enhancement of the efficiency of dye-sensitized solar cell by utilizing carbon nanotube counter electrode”, Scripta Materialia 62 148-150 (2010)

“Fabrication of Complex-shaped Alumina/Nickel Nanocomposites by GelcastingProcess", Journal of the European Ceramic Society, 24 [12] 3419-3425 (2004)

Performance

Development of smelting/refining technology of 4N5 ultra-high purity molybdenum with high melting point for semiconductor materials utilizing northern resources (2020~2024)

Development of one-dimensional FeNdB exchange coupling magnets manufacturing technology (2017~2020)

Development of High entropy alloys (2018~2020)

Development of high sensitive and functional organic.inorganic hybrid plastic composite for LED (2015~2018)

Details

Position

Principal Research

Major

Convergence Manufacturing System Engineering

Affiliation

Research Institute of Intelligent Manufacturing &

Division

Research Institute Intelligent Manufacturing &Mate

vlvwlw@kitech.re.kr

Homepage

TEL

032-850-0468

Education

1994-02 / Inha University / Bachelor's

1996-02 / Inha University / Master's

2002-02 / Inha University / Doctor's

Representative Study

- Effect of Heat Treatment Residual Stress on Stress Behavior of Constant Stress Beam(2018, Journal of Compute Design Engineering)

- Design and Evaluation of the Thermal Capability to Secure a Working Time of Cryogenic Explosion-proof Camera in LNG Carrier Tank (2017, SCIE, INTERNATIONAL JOURNAL OF NAVAL ARCHITECTURE AND OCEAN ENGINEERING)

- Thermal stress analysis method considering geometric effect of risers in sand mold casting process (2014, SCIE,CHINA FOUNDRY)

- Effects of displacement boundary conditions on thermal deformation in thermal stress problems(2013, SCIE,CHINA FOUNDRY)

Performance

- Structural safety evaluation of 12-inch marine loading arm

- Development of large-scale high-quality aluminum sand casting technology

- Development of large aluminum permanent mold casting process technology for 550mm gate diameter pendulum valves for semiconductor/display devices

Details

Position

Professor

Major

Industrial Technology

Affiliation

UST-KITECH School

Division

Inteligent Manufacturing R&D Department

ischo@kitech.re.kr

Homepage

TEL

031-8084-8803

Education

1991-02 / Yonsei University / Bachelor's

1992-02 / Yonsei University / Master's

1997-08 / Yonsei University / Doctor's

Representative Study

IS Cho, KD Savelyev, VM Golod/Development of thermophysical calculator for stainless steel casting alloys by using CALPHAD approach/China Foundry/2017.8

IS Cho, CP Hong/Modeling of microstructural evolution in squeeze casting of an Al-4.5 mass% Cu alloy/ISIJ International/1997

IS Cho, CP Hong/Evaluation of heat-transfer coefficients at the casting/die interface in squeeze casting/IJCMR,/1996

Performance

Details

Position

Professor

Major

Industrial Technology

Affiliation

UST-KITECH School

Division

Advanced Materials and Proces R&D Department

shae@kitech.re.kr

Homepage

TEL

032-8500-412

Education

1995-02 / Sungkyunkwan University / Bachelor's

1997-02 / Sungkyunkwan University / Master's

2001-02 / Sungkyunkwan University / Doctor's

Representative Study

Kim et al., Magnesium-based Alloy for High Temperature and Manufacturing Method Thereof, US 8,808,423 B2, Aug. 19, 2014

Kim et al., Manufacturing Method of Aluminum Alloy, EP 2339037, Aug. 18, 2013

S. K. Kim, Design and Development of High-Performance Eco-Mg Alloys, in: Magnesium Alloys - Design, Processing and Properties, 1st ed., InTech, Rijeka, 2011, pp. 431-468.

Performance

Optimization of Thermomechanical Process for ECO-Almag Novel Sheet Alloys

Development for High Strength-High Ductility Al Alloys for HPDC

Development of Roll-Rod Bracket by HPDC

Alloy Design and Process Development for Super-Strength ECO-Almag(6-10)-X Alloys

Details

Position

Representative Professor

Major

Industrial Technology

Affiliation

UST-KITECH School

Division

Vice President

tskim@kitech.re.kr

Homepage

TEL

032-850-0409

Education

1990-02 / Chungbuk National University / Bachelor's

1992-02 / Chungbuk National University / Master's

1998-02 / Chungnam National University / Doctor's

2004-04 / Tohoku University / Doctor's

Representative Study

T.S.Kim et al., Experimental investigation of diffusion behavior between molten Mg and Nd-Fe-B magnets, Journal of Alloys and Compounds, Vol. (2013) in printing

가스 분무 공정을 이용한 Nd-Fe-B 자성분말의 제조방법, 자성분말, 자성체 및 자성체의 제조방법 (10-2012-142448)

T.S.Kim et al., Effect of rapid cooling and extrusion ratio on the mechanical property of Mg alloys, Journal of Alloys and Compounds, Vol.504 (2010) 496 -499

Performance

Mg을 이용한 희토자석의 고기능 순환 소재화 기술 개발

미래분말소재 경쟁력 확보를 위한 Fe계 분말 제조 기술 개발

수소가스 운송을 위한 사용압력 450bar이상, 내용적 300리터 이상의 복합재료 압력용기 개발

용탕 분사형 Atomizing 법을 이용한 Nd계 자석 제조기술 개발

희소금속산업 육성 인프라구축

한-러 기술협력 플랫폼 구축사업

고순도 중희토류 추출을 위한 친환경 pyrometallurgy process 개발 및 소재화 기술개발

지속가능한 국내 희토류 산업 활성화를 위한 국제 표준 개발

Details

Position

Associate Professor

Major

Industrial Technology

Affiliation

UST-KITECH School

Division

Inteligent Manufacturing R&D Department

j.park@kitech.re.kr

Homepage

TEL

031-8084-8835

Education

2008-08 / Hanyang University / Bachelor's

2010-08 / Hanyang University / Master's

2017-08 / Korea Advanced Institute of Science and Technology / Doctor's

Representative Study

Additive manufacturing of a shift block via laser powder bed fusion: the simultaneous utilisation of optimised topology and a lattice structure[VIRTUAL AND PHYSICAL PROTOTYPING,2020-09-15]

Simultaneous 3D surface profling of multiple targets by repetition rate scanning of a single femtosecond laser[INTERNATIONAL JOURNAL OF PRECISION ENGINEERING AND MANUFACTURING,2020-02-01]

Rigorous single pulse imaging for ultrafast interferometric observation[OPTICS EXPRESS,2019-07-08]

Performance

Jiyong Park, Seungman Kim, Byung Soo Kim, Young-Jin Kim and Seung-Woo Kim / Tuning range extension of pulse repetition rate using chirped fiber Bragg gratings / Optics Express / 2017.01.23.

Yang Lu*, Jiyong Park*, Dian Bian, Liandong Yu, Seung-Woo Kim / Simultaneous 3-D surface profiling of multiple targets by repetition rate scanning of a single femtosecond laser / IJPEM / 2020.02.01.

Yang Lu*, Jiyong Park*, Liandong Yu and Seung-Woo Kim / 3D profiling of rough silicon carbide surfaces by coherence scanning interferometry using a femtosecond laser / Applied Optics / 2018.04.01.

Details

Position

Principal Researcher / Head of Center

Major

Industrial Technology

Affiliation

Research Institute of Intelligent Manufacturing

Division

Manufacturing AI Research Center

rebirth@kitech.re.kr

Homepage

TEL

032-850-0290

Education

2003-02 / Kyungpook National University / Bachelor's

2009-08 / Pohang University of Science and Technology / Doctor's

Representative Study

Jong Pil Yun, Woosang Crino Shin, Gyogwon Koo, Min Su Kim, Chungki Lee, Sang Jun Lee / Automated defect inspection system for metal surfaces based on deep learning and data augmentation / Journal of Manufacturing Systems / 2020

Min Su Kim, Jong Pil Yun, PooGyeon Park / An Explainable Convolutional Neural Network for Fault Diagnosis in Linear Motion Guide / IEEE Transactions on Industrial Informatics / 2021

Woosang Shin, Jonghyeon Lee, Taehan Lee, Sangmoon Lee, Jong Pil Yun / Anomaly detection using score-based perturbation resilience / ICCV / 2023

Performance

Automated brittle fracture rate estimator for steel property evaluation using deep learning after drop-weight tear test[IEEE ACCESS,2019-10-04]

Prediction of the temperature of liquid aluminum and the dissolved hydrogen content in liquid aluminum with a machine learning approach[METALS,2020-03-02]

Automated defect inspection system for metal surfaces based on deep learning and data augmentation[JOURNAL OF MANUFACTURING SYSTEMS,2020-04-30]

Deep learning based discrimination of soft tissue profiles requiring orthognathic surgery by facial photographs[SCIENTIFIC REPORTS,2020-10-01]

Deep learning based prediction of extraction difficulty for mandibular third molars[SCIENTIFIC REPORTS,2021-01-21]

Deep-learning for predicting C-shaped canals in mandibular second molars on panoramic radiographs[DENTOMAXILLOFACIAL RADIOLOGY,2021-01-06]

Unified deep neural networks for end-to-end recognition of multi-oriented billet identification number[EXPERT SYSTEMS WITH APPLICATIONS,2021-04-15]

An explainable convolutional neural network for fault diagnosis in linear motion guide[IEEE TRANSACTIONS ON INDUSTRIAL INFORMATICS,2021-06-01]

Deep learning based prediction of necessity for orthognathic surgery of skeletal malocclusion usin cephalogram in Korean individuals[BMC ORAL HEALTH,2021-03-18]

Deep-learning-baed detection of cranio-spinal differences between skeletal classification using cephalometric radiography[DIAGNOSTICS,2021-03-25]

Linearly sensitive pressure sensor based on a porous multistacked composite structure with conrolled mechanical and electrical properties[ACS APPLIED MATERIALS & INTERFACES,2021-06-23]

An explainable neural network for fault diagnosis with a frequency activation map[IEEE ACCESS,2021-07-08]

Deep learning neural networks to differentiate stafne's bone cavity from pathological radiolucent lesions of the mandible in heterogeneour panoramic radiography[PLOS ONE,2021-07-20]

Deep learning-based prediction of paresthesia after thrid molar extraction: a preliminary study[DIAGNOSTICS,2021-08-30]

Multi-channel object detection for detecting suspected trees with pine wilt disease using multispectral drone imagery[IEEE JOURNAL OF SELECTED TOPICS IN APPLIED EARTH OBSERVATIONS AND REMOTE SENSING,2021-08-04]

Automatic brittle fracture ratio estimation using convolutional neural network regression based on classmap regulation[IEEE ACCESS,2021-10-05]

Three-dimensional postoperative results prediction for orthognathic surgery through deep learning-based alignment network[JOURNAL OF PERSONALIZED MEDICINE,2022-06-18]

Attention-based multimodal image feature fusion module for transmission line detection[IEEE TRANSACTIONS ON INDUSTRIAL INFORMATICS,2022-11-01]

Deep learning-based explainable fault diagnosis model with an individually grouped 1-D convolution for three-axis vibration signals[IEEE TRANSACTIONS ON INDUSTRIAL INFORMATICS,2022-12-01]

Robust and explainable fault diagnosis with power-perturbation-based decision boundary analysis of deep learning models[IEEE TRANSACTIONS ON INDUSTRIAL INFORMATICS,2023-05-01]

Deep learning synthesis of cone-beam computed tomography from zero echo time magnetic resonance imaging[SCIENTIFIC REPORTS,2023-04-13]

Details

Position

Major

Industrial Technology

Affiliation

Division

3D Printing Manufacturing Innovation Center

leehyub@kitech.re.kr

Homepage

TEL

031-8084-8828

Education

2009-02 / Korea Advanced Institute of Science and Technology / Bachelor's

2011-02 / Korea Advanced Institute of Science and Technology / Master's

2016-02 / Korea Advanced Institute of Science and Technology / Doctor's

Representative Study

- Lee, Hyub, Chin Huat Joel Lim, Mun Ji Low, Nicholas Tham, Vadakke Matham Murukeshan, and Young-Jin Kim./Lasers in additive manufacturing: A review/International Journal of Precision Engineering and Manufacturing-Green Technology/12 July 2017

- Lee, Hyub, Mun Ji Low, Chin Huat Joel Lim, Jianing An, CS Suchand Sandeep, Thazhe Madam Rohith, Hyug-Gyo Rhee, Vadakke Matham Murukeshan, and Young-Jin Kim/Transferable ultra-thin multi-level micro-optics patterned by tunable photoreduction and photoablation for hybrid optics/Carbon/23 April 2019

- Park, Sangbaek*, Hyub Lee*, Young-Jin Kim, and Pooi See Lee/Fully laser-patterned stretchable microsupercapacitors integrated with soft electronic circuit components/NPG Asia Materials/03 October 2018

Performance

Treatise(Recent 5 yesrs)- Effects of Pre- and Post-heat treatments on Microstructure and Tensile Behaviors of 630 Stainless Steel Repaired by Metal Additive Manufacturing[JOURNAL OF MATERIALS RESEARCH AND TECHNOLOGY-JMR&T,2021-05-27]

- A Preliminary Study on the Lamination Characteristics of Inconel 718 Superalloy on S45C Structural Steel using LENS Process[한국기계가공학회지,2021-01-31]

- Effects of Deposition Strategy and Preheating Temperature on Thermo-Mechanical Characteristics of Inconel 718 Super-Alloy Deposited on AISI 1045 Substrate Using a DED Process[MATERIALS,2021-04-05]

- Additive Manufacturing of a Shift Block via Laser Powder Bed Fusion: the Simultaneous Utilisation of Optimized Topology and a Lattice Structure[VIRTUAL AND PHYSICAL PROTOTYPING,2020-09-15]

- Attachable Micropseudosapacitors Using Highly Swolen Laser-induced-graphene Electrodes[CHEMICAL ENGINEERING JOURNAL,2019-12-27]

- Laser-induced Reduced-graphene-oxide Micro-optics Patterned by Femtosecond Laser Direct Writing[APPLIED SURFACE SCIENCE,2020-05-21]

- Transferable Ultra-thin Multi-level Micro-optics Patterned by Tunable Photoreduction and Photoablation for Hybrid Optics[CARBON,2019-04-23]

- Coherent Power Amplification of Third-order Harmonic Femtosecond Pulses at Thin-film Up-conversion Nanoparticles[SCIENTIFIC REPORTS,2019-03-25]

- Fully Laser-patterned Stretchable Microsupercapacitors Integrated with Soft Electronic Circuit Components[NPG ASIA MATERIALS,2018-10-03]

- Nonlinear Third Harmonic Generation at Crystalline Sapphires[OPTICS EXPRESS,2017-10-11]

- Lasers in Additive Manufacturing: A Review[INTERNATIONAL JOURNAL OF PRECISION ENGINEERING AND MANUFACTURING-GREEN TECHNOLOGY,2017-05-21]

- 에너지 제어 용착을 이용한 스테인리스 316L의 적층 특성 및 기계적 물성 평가[한국기계가공학회지,2021-06-20]

- Selective compositional range exclusion via directed energy deposition to produce a defect-free Inconel 718/SS 316L functionally graded material[ADDITIVE MANUFACTURING,2021-09-08]

Details

Position

Principle Researcher

Major

Industrial Materials and Smart Manufacturing Engin

Affiliation

Korea Institute of Rare Metal

Division

Manufacturing Technology Office

sjseo@kitech.re.kr

Homepage

TEL

+82 32 458 5114

Education

2004-02/KAIST/Bachelor's

2006-08/KAIST/Master's

2011-08/KAIST/Doctor's

Representative Study

Full-Color Phosphors with Rare Earth Complex

Rare Metal Free Oxide Thin Film Transistors

Eco-Friendly Process for Rare Earth Recycling

Performance

Technology for the eco-friendly rare earth refining from used motors and manufacture of permanent magnet materials

High purity metal refining technology for titanium metal with zero toxic gas(chlorine and fluorine) emission

Development of synthesis technology of high surface area mesoporous copper based metal oxides using inverse micelle for electrochemical application

Development of high efficiency hydrogen production system using high frequency induction heating

Details

Position

Senior Researcher

Major

Affiliation

Research Institute of Advanced Manufacturing&Mater

Division

Advanced Joining and Additive Manufacturing R&D De

cwha@kitech.re.kr

Homepage

TEL

031-8084-8827

Education

2009 / KAIST / Bachelor's

2011 / KAIST / Master's

2016 / KAIST / Doctor's

Representative Study

Sequential process optimization for a digital light processing system to minimize trial and error, Scientific Report, 2022

Performance

(MOTIE) Development of Modular Continuous Flow Reaction System for High Purity 5G Low Dielectric Material Using DfAM-based 3D Printing

Details

Position

Professor

Major

Industrial Materials and Smart Manufacturing Engin

Affiliation

KITECH

Division

Additive Manufacturing Innovation Agency

sonyong@kitech.re.kr

Homepage

TEL

031-8084-8824

Education

2006 / Hanyang University / Bachelor's

2008 / KAIST / Master's

2013 / KAIST / Doctor's

Representative Study

Additive manufacturing of a shift block via laser powder bed fusion: the simultaneous utilisation of optimised topology and a lattice structure, VIRTUAL AND PHYSICAL PROTOTYPING, 2020

Performance

Development of Metal 3D Printing Production and Maintenance Commercialization Technology for National Defense Demands (2018~2021)

Demonstration support of 3D printing industrial parts industrial technology (2020~2023)

Development of DfAM-based 3D Printing technology for combustor parts of private sector initiative small space launcher engine(2022~2024)

Details

Position

Professor

Major

Materials Science and Engineering

Affiliation

KITECH

Division

Korea Institute for Rare Metal

ktpark@kitech.re.kr

Homepage

TEL

0322261351

Education

2007 / Chungnam National University / Bachelor of Engineering

2010 / Chungnam National University / Master of Engineering

2013 / Chungnam National University / ph.D of Engineering

Representative Study

Effects of reduction temperature and diluent content on the properties of high-purity tantalum powder prepared using the Hunter process, International Journal of Refractory MEtals and Hard Materials 112: 106128, 2023.

Kinetic study of electrochemical deoxidation of commercially pure titanium in molten magnesium chloride, Journal of Materials Science, 1-17, 2023.

Effective Deoxidation Process of Titanium Scrap Using MgCl2 Molten Salt Electrolytic, Metals, 11(12), 1981, 2021.

Removal of Mg and MgO By-Products through Magnesiothermic Reduction of Ti Powder in Self-Propagating High-Temperature Synthesis, Metals, 9(2), 169, 2019.

Pre-treatments of initial materials for controlling synthesized TaC characteristics in the SHS process, Jounal of Powder Materials, 25(3), 251-256, 2018.

Performance

Development of manufacturing technology for lithium-based cathode materials with a purity of over 99% using an eco-friendly new method from secondary battery scrap black powder

Development of deoxidation refining process using off grade Ti scrap over 100 kg per day for the production of 4N5 grade ingot and utilizing

Development of platform process using common core and materialization technology for rare metal recovery from industrial low-grade waste

Development of recycling technology for tungsten waste (2 ton/year) in photolithography lamp, a by-product of semiconductor precess

Development of eco-friendly smelting technology for the production of rare metal production for lowering manufacturing costs using solid oxide membrane

Details

Position

Professor

Major

Materials Science and Engineering

Affiliation

KITECH

Division

Carbon & Light Materials Application R&D Group

raykim@kitech.re.kr

Homepage

TEL

0632103715

Education

2008 / Jeonbuk Univ. / Bachelor

2010 / Tokyo Institute of Technology / Master

2012 / Tokyo Institute of Technology / Doctor

Representative Study

Microstructural evolution at the initial stage of two-step aging in an Al-Mg-Si alloy characterized by a three dimensional atom probe, Materials Science & Engineering A, Vol 815, pp 141031, 2021

Enhanced mechanical properties of Al–Si–Cu–Mg(-Fe) alloys by a deformation-semisolid extrusion process, Materials Science & Engineering A, Vol 825, pp 141667, 2021

Using multiple regression analysis to predict directionally solidified TiAl mechanical property, Journal of Materials Science & Technology, Vol 104, pp 285-291, 2021

Machine learning prediction of the mechanical properties of -TiAl alloys produced using random forest regression model, Journal of Materials Science & Technology, Vol 18, pp 520-530, 2022

Clustering evolution during low temperature aging and thermal stability during two-step aging in Al-Mg-Si alloys, Journal of Alloys and Compounds, Vol 946, pp 169291, 2023

Performance

Development of heat treatment technology for high strength aluminum alloys based on control of cluster formation below 2nm using 3 dimensional atom probe

Development of 3.0 GPa% grade aluminum material and casting analysis technology for high vacuum die casting

Commercialization development of 3Bar watertight performance inverter housing for electric vehicle applying machine learning based dissimilar friction stir welding

Details

Position

Principal Researcher

Major

UST/Industrial Materials and Smart Manufacturing E

Affiliation

Seonam Technology Application Division(Purpose Bui

Division

Energy & Nano Technology Group

thseo@kitech.re.kr

Homepage

TEL

+82-62-600-6530

Education

2008 / Chonbuk National University / Bachelor's

2010 / Chonbuk National University / Master's

2014 / Chonbuk National University / Doctor's

Representative Study

Dominant formation of h-BC2N in h-BxCyNz films: CVD synthesis and characterization / 2021

Graphene-Based PDLC Device Enabled by Water-Induced Interface Cleaning Process/ 2023

Bayesian Optimization of Wet-Impregnated Co-Mo/Al2O3 Catalyst for Maximizing the Yield of Carbon Nanotube Synthesis / 2024

Performance

Research on characteristics of purpose-oriented multidimensional semiconductor material-based flexible devices

Development of process technology for graphene-based OLED lighting

Research on semiconductor nanosensor materials/devices for future and autonomous vehicles

Details

Position

Principal Researcher

Major

Materials Science and Engineering

Affiliation

KITECH

Division

Industrial Transformation Technology Department

hak1414@kitech.re.kr

Homepage

TEL

041-589-8553

Education

2010 / Korea Advanced Institute of Science and Technology / Bachelor

2017 / Korea Advanced Institute of Science and Technology / Ph. D

Representative Study

Development of Air Bearing Stage Using Flexure for Yaw Motion Compensation, Actuators / 2022

Optimal Design of the Electroadhesion Pad with a Dual-Insulating Layer for Climbing Robots, Actuators / 2022

Vibration Damped Tool Holders in Industrial Robotic Machining Systems, IJPEM / 2023

Development of an ultrasonic-assisted soldering system for Fe-based lead frame surface coating, JMST / 2023

Development of Wafer Bonding System for High Precision Bonding Alignment, IJPEM / 2024

Performance

[Ministry of Trade, Industry and Energy] Development of commercialization technology for bonding/debonding equipment and adhesives for ultra-thin wafer handling for HBM manufacturing – 2022~2025

[Ministry of Trade, Industry and Energy] Micro semiconductor socket for high-density semiconductor inspection – 2023~2025

[Industrial Project-SEMES] Development of 6-degree-of-freedom stage – 2023~2025

[Ministry of Trade, Industry and Energy] Development of robot processing system for milling/routing/trimming processing with smart workpiece holder and smart gripper – 2021~2024

[Ministry of SMEs and Startups] Development of ultra-precision motion stage standard platform for semiconductor preprocess inspection/measurement/high-vacuum equipment – 2021~2025

[Ministry of SMEs and Startups] Development of UTG (Ultra-Thin Glass) property reinforcement coating process and equipment for foldable IT devices (smartphones/tablets/laptops) – 2021~2024

[Ministry of Land, Infrastructure and Transport] Smart logistics center Development of core technology for magnetic levitation multi-parallel transport and sorting system – 2020~2022

[Industrial Project] Basic design and test support service for single-axis actuator performance test device – 2021~2024

Details

Position

Senior Researcher

Major

Green Process and Energy System Engineering

Affiliation

UST-KITECH SCHOOL

Division

Low-carbon Emission Control Technology R&D Departm

ksungil85@kitech.re.kr

Homepage

TEL

041-589-8403

Education

2012 / Sungkyunkwan Univ. / Bachelor's

2014 / KAIST / Master's

2019 / KAIST / Doctor's

Representative Study

Publications (SCI)

● Evaluation of effects of ammonia co-firing on the thermal performances of supercritical pulverized coal and circulating fluidized bed boilers, Energy Conversion and Management) / 2023

● Assessment of energy self-sufficiency of a smart farm through integrated modeling of air-source heat pumps and solar power generation, Applied Energy) / 2024

● Improving waste-incineration energy recovery efficiency using a reverse calculation algorithm to estimate waste composition and heating value, Waste Management) / 2024

Performance

● Development of AI based prototyping SW advancement technology for intelligent conversion of energy field (COMPA, 24.04~25.12)

● Development and demonstration of Ammonia 20% co-combustion technology for Power generation CFB boilers (KETEP, 23.04~27.12)

● Development of combined cycle of magnetohydrodynamics(MHD) and hydrogen gas turbine with turquoise hydrogen (NST, 22.06~27.05)

● Optimization of energy-environment integrated management using modeling, data prediction and analysis (KETEP, 22.04~25.03)

● Development and demonstration of 2 ton/hr industrial hydrogen boiler (KEIT, 23.04~26.12)

● Development of 10Kg_H2/day hydrogen production technology by natural gas pyrolysis with molten metal catalysts (KETEP, 24.07~26.12)

Details

Position

Principal Researcher

Major

Industrial Materials and Smart Manufacturing Engin

Affiliation

UST-KITECH SCHOOL

Division

Customized Manufacturing R&D Department

cahn@kitech.re.kr

Homepage

TEL

031-8084-8634

Education

2010 / Sungkyunkwan Univ. / Bachelor's

2016 / Sungkyunkwan Univ. / Doctor's

Representative Study

A study of highly activated hydrogen evolution reaction performance in acidic media by 2D heterostructure of N and S doped graphene on MoOx, Carbon Energy / 2023

Synthesis of multiphase MoS2 heterostructures using temperature-controlled plasma-sulfurization for photodetector applications, Nanoscale / 2023

Friction characteristics of molybdenum disulfide thin films synthesized via plasma sulfurization, Advanced Engineering Materials / 2021

Performance

Development of multifunctional high conductivity-corrosion coating technology for high performance of semiconductor inspection probe

Development of stacking technology of self-lubrication nanostructure by CVD process

Development of combined process technology of electrochemical etahing and CMP for hybrid bonding

Details

Position

Principal Researcher

Major

Green Process and Energy System Engineering

Affiliation

UST-KITECH SCHOOL

Division

Jeju Technology Application Division

ohs8680@kitech.re.kr

Homepage

TEL

0647541534

Education

2005 / Jeju National University / Bachelor's

2008 / Jeju National University / Master's

2014 / Jeju National University / Doctor's

Representative Study

Performance and feasibility assessment of an adsorptive-dehumidification system utilizing a heat pipe-based desiccant-coated heat exchanger / 2005

Numerical Study on the performance of a heat pump-driven-DCMD for sustainable desalination/2022

Heat and Mass Transfer of a Decoupling Cooling System: A Desiccant-Coated Heat Exchanger and a Dew-Point Evaporative Cooler/2022

Performance

Ministry of Science and ICT/ Development of Multi-Sector Coupling Core Technology for Increasing Receptivity of Variable Renewable Energy/ 2024.07.01.~2025.06.30.

Ministry of Trade, Industry and Energy/ Development of P2Heat Technology Using Renewable Energy Curtailment/ 2022.04.01.~2025.12.31.

Development of Buffer Functional Materials and Active Utilization System for Urban Climate Change/ 2023.05.01.~2026.12.31.

Details

Position

Principal Researcher

Major

Industrial Materials and Smart Manufacturing Engin

Affiliation

UST-KITECH SCHOOL

Division

Flexible Manufacturing R&D Department

youngmin@kitech.re.kr

Homepage

TEL

032-850-0240

Education

2005 / Seoul National University / Materials Science and Engineering B.S.

2007 / Seoul National University / Materials Science and Engineering M.S.

2012 / Stanford University / Materials Science and Engineering Ph.D.

Representative Study

High performance soft magnetic composites with optimized Fe3O4 coating layer using rotary reactor-based sputtering, Materials & Design 114428 (2025)

Atomically doped carbon on highly porous nickel sulfide for efficient hydrogen evolution reaction, International Journal of Hydrogen Energy 102 (2025) 909-917

Quantitative detection of dopamine in human serum with surface-enhanced Raman scattering (SERS) of constrained vibrational mode, Talanta, 260 (2023)

Selective photoactive gas detection of CO and HCHO using highly porous SnO2 and SnO2@ TiO2 heterostructure, Sensors and Actuator B 358 (2022)

Performance

Details

Position

Principal Researcher

Major

Industrial Materials and Smart Manufacturing Engin

Affiliation

UST-KITECH SCHOOL

Division

3D Printing Manufacturing Process Center

jhjh@kitech.re.kr

Homepage

https://scholar.google.com/citations?hl=ko&user=4VYgAn0AAAAJ

TEL

052-980-6006

Education

2012-02 / POSTECH / Bachelor's

2019-02 / POSTECH / Doctor's

Representative Study

Ha, J.* / Enhancement of Mechanical Properties and Hydrogen Embrittlement Resistance of Laser Directed Energy Deposition Fabricated 316L Stainless Steel by Laser Shock Peening / Applied Sciences / 2025

Kim, J. G., Kim, C. S., Park, S. H., & Ha, J.* / Effect of Angle of Incident on Taper Angle in Femtosecond Laser Machining for Fabrication of Cross Section Analysis Specimen / Korean Journal of Metals and Materials / 2024

Ha, J.*, Noh, J., Jung, Y. J., Liang, W., Choi, T. Y., Kim, J., & Kim, D. / High compaction and physical graphitization of CNT bundles and network via extreme-load compression using laser-induced shockwave / Carbon / 2023

Performance

Development of Dual-Step Photon Beam Processing Technology for Optical/Charged Particle Triple-Beam Systems (Apr. 2022 – Dec. 2025, Ministry of Science and ICT, Total Budget: 6.3B KRW / KITECH: 1.4B KRW)

Empirical Knowledge-Sharing-Based Artificial Intelligence Predictive Maintenance Platform (Apr. 2022 – Dec. 2025, Ministry of SMEs and Startups, Total Budget: 4.8B KRW / KITECH: 0.6B KRW)

Development of Intelligent Design Technology for Customized Manufacturing Support Based on AI-Driven Product Demand Forecasting (Apr. 2022 – Dec. 2025, Ministry of SMEs and Startups, Total Budget: 4.0B KRW / KITECH: 0.84B KRW)

Demonstration of Large-Area Composite Material Additive Manufacturing Equipment for Press Die Production (Apr. 2022 – Mar. 2023, Ministry of Trade, Industry and Energy, Total Budget: 1.0B KRW / KITECH: 0.16B KRW)

Development of Room-Temperature Forming Technology for Magnesium Alloys Using Laser-Induced Shock Waves (Mar. 2020 – Feb. 2023, Ministry of Science and ICT, Total Budget: 0.45B KRW)

Development of Reliability Assurance Technology Using Load Cell Sensors for High-Pressure Die Casting Process Equipment (May 2021 – Apr. 2022, Ministry of SMEs and Startups, Total Budget: 0.12B KRW)

Development of Low-Energy Laser Peening Technology to Improve Mechanical Properties of Complex-Shaped Components (Jan. 2021 – Dec. 2021, Ministry of Economy and Finance, Total Budget: 0.03B KRW)

Details

Position

Principal Researcher

Major

Industrial Materials and Smart Manufacturing Engin

Affiliation

UST-KITECH SCHOOL

Division

Smart Forming Process Group

jwko@kitech.re.kr

Homepage

TEL

052-980-6003

Education

2010 / Hanyang University / Bachelor's

2012 / Korea Advanced Institute of Science and Technology / Master's

2017 / Korea Advanced Institute of Science and Technology / / Doctor's

Representative Study

Material extrusion for ceramic additive manufacturing with polymer-free ceramic precursor binder, Materials & Design / 2022

Evaluation of cooling performance of additive manufactured gravity die casting mold with conformal cooling channel, Korean Journal of Metal and Materials / 2021

Self-Assembled Peptide-Carbon Nitride Hydrogel as a Light-Responsive Scaffold Material, Biomacromolecules / 2017

Performance

Development of AI-based high carbon steel alloy design and sintering-based additive manufacturing technology for 7.0 L/Hr-level high-speed production of powertrain components with tensile strength over 1.0 GPa, MOTIE / in progress

Development of international standards for reliability evaluation methods of wafer dicing technology for power semiconductors, MOTIE / in progress

Details

Position

Principal Researcher

Major

Industrial Materials and Smart Manufacturing Engin

Affiliation

UST-KITECH SCHOOL

Division

Korea National Institute of Rare Metals

shinclusion@kitech.re.kr

Homepage

TEL

032-458-5798

Education

2017 / Hanyang university / Doctor's

2013 / Ulsan university / Master's

2011 / Ulsan university / Bachelor's

Representative Study

Electrochemical lithium recovery from waste secondary batteries by direct electrolysis in molten lithium carbonate/ELECTROCHIMICA ACTA/2025

Electrochemical performance and behavior of nickel pig Iron anodic electrolysis for enhanced sulfuric acid leaching/ELECTROCHEMISTRY COMMUNICATIONS/2025

Titanium deoxidation mechanism probed using an electron beam melting method/ELECTROCHEMISTRY COMMUNICATIONS/2025

Mechanisms and Kinetics for Pyrometallurgical Recovery of Zinc and Manganese Oxides from Spent Alkaline and Zinc-C Batteries/Mineral Processing and Extractive Metallurgy Review/2025

Pyrometallurgical eco-recycling for Zn and MnO recovery from spent alkaline and Zn–C batteries/Journal of Material Cycles and Waste Management/2025

Performance

Development of Integrated Ni/Cr Materialization Technology based on New Metallurgy Technology from Waste Scrap containing Ni(2024-09-01 ~ 2028-12-31)

Development of manufacturing process with high recovery rate for high purity nickel sulfate using nickel-contained waste(2024-07-01 ~ 2028-12-31)

Development of high alloy steel ingots with a carbon content less than 0.03% using waste molds and tools(2024-07-01 ~ 2027-12-31)

Development of manufacturing technology for lithium-based cathode materials with a purity of over 99% using an eco-friendly new method from secondary battery scrap black powder(2022-04-01 ~ 2026-12-31)

Development of Nickel HPAL Technology and High Purity Nickel sulfate Manufacturing Technology(2025-04-01 ~ 2029-12-31)

Development of Eco-friendly, Low cost, and High-efficiency Nickel Recovery Process (100ton/year scale) from Nickel Pig Iron (NPI)(2023-07-17 ~ 2027-07-16)

Development of recycling and value-added technologies for semiconductor/display process waste water with molybdenum(2025-05-01 ~ 2026-04-30)

Development of a multi-stage electrolysis/precipitation complex process for extracting high-purity palladium of 99% or more from electronic waste.(2023-07-17 ~ 2025-07-16)

Development of Eco-friendly process for rare earth recycling and permanent magnet manufacturing using waste motors(2020-04-01 ~ 2024-12-31)

Fluorescent synthetic analyzer

Holding Area

Incheon

Equipment Description

희토류 컨텀닷 형광체의 실시간 배합 및 평가 모니터링 시스템

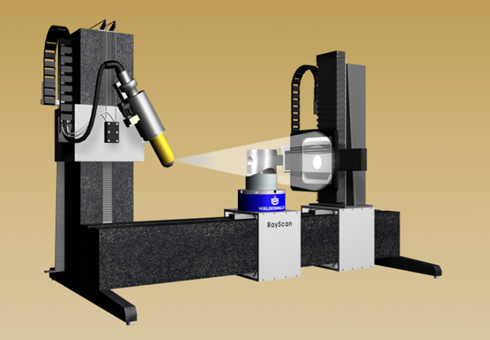

Industrial CT-computed tomography

Holding Area

Incheon

Equipment Description

의료용 단층촬영기(CT)를 산업용을 목적으로 하여 3차원적 고성능을 갖춘 기능으로 발전시킨 장비이며 X-ray투시에 의해 각종 금속,비금속 소재 및 부품 등의 내부결함, 형상, 치수 등 다양한 특성을 신속,정확하게 분석 할 수 있는 장비입니다.

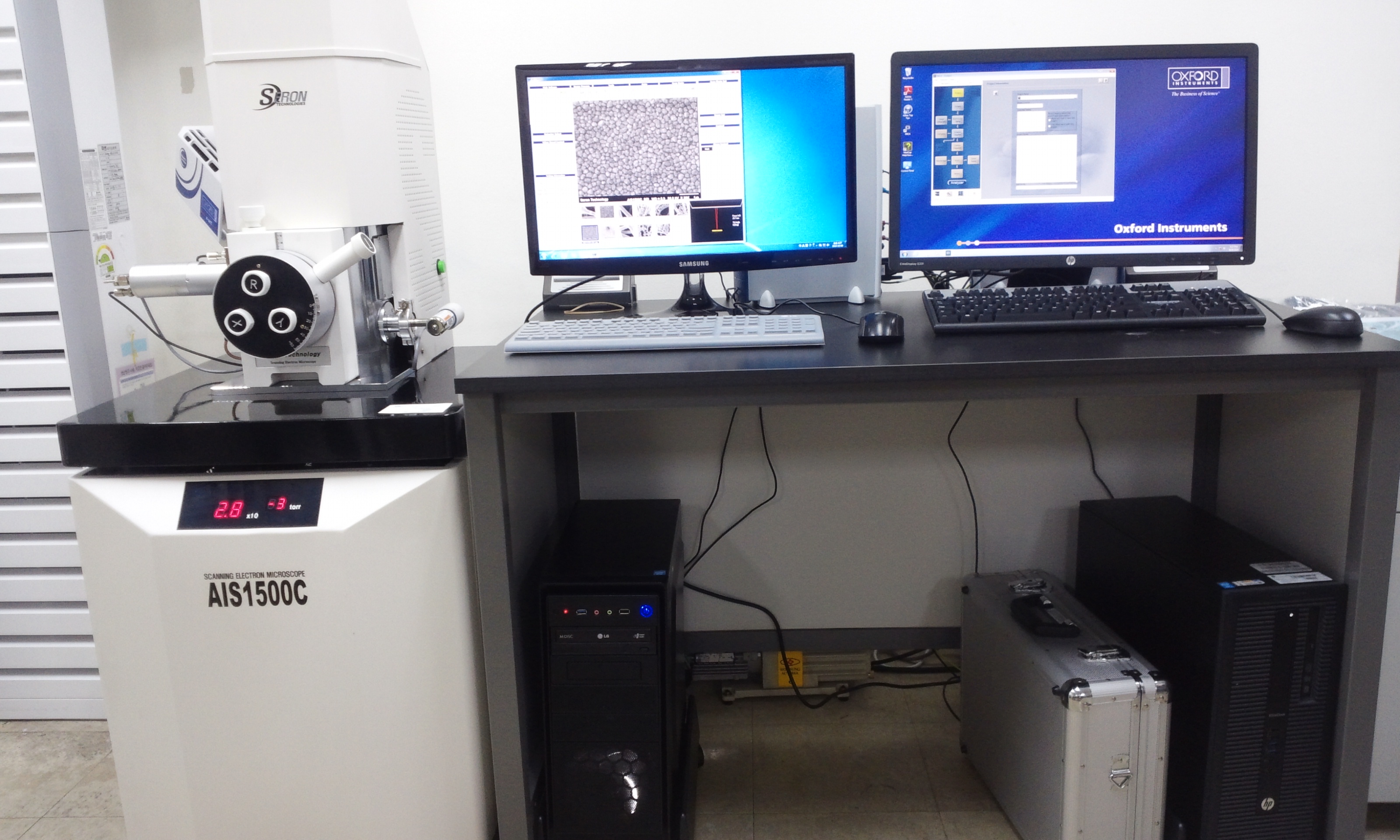

Scanning electron microscope

Holding Area

Incheon

Equipment Description

신소재 표면의 미세한 구조를 확대 관찰하는 전자현미경

New alloy powder manufacturing equipment for 3D pr

Holding Area

Incheon

Equipment Description

용융 금속에 고압의 가스를 분사하여 3D프린팅용 등의 신소재 분말을 제조하는 첨단장비

Semiconductor chip bonder

Holding Area

Incheon

Equipment Description

초소형 반도체칩의 접합 실험장비

Glow discharge mass spectrometer

Holding Area

Incheon

Equipment Description

신소재의 첨가원소 및 불순물을 ppm(백만분의 일) 단위까지 측정하는 초고분해능 성분 분석기

'There is no such information.'