Gas chromatography

Holding Area

Ulsan

-

Equipment Description

휘발성 시료를 구성한 물질이 얼마나 있는지를 규명하는데 사용되는 보편화된 장비로 단일화합물이 컬럼을 빠져나온 시간과 검출기 감응에 대한 면적을 통해 정성 정량 분석이 가능한 장치

UST-KITECH School

Convergence Manufacturing system Engineering

Green Process and Energy System Engineering

The Department of Green Process and Energy System Engineering studies clean materials, processes, and high-efficiency energy technologies essential for converting Korea's industrial structure into a low-carbon economic structure to enable sustainable industrial development. The department also aims to foster green technology professionals in the chemical industry, including minimizing pollutants, producing eco-friendly raw materials and products, resource recycling technology, and in the (2) energy industry, reducing greenhouse gas emission, digitalization of energy plants, high efficiency energy production technology using unused resources such as biomass, low grade fuel and waste, and high-efficiency design technology for thermal fluid machines.

Course Objectives

This lecture aims at understanding fundamental theories of clean combustion engineering including gas, liquid and solid fuels. Various engineering approaches for physico-chemical phenomena of combustion will be presented.

Course Objectives

This lecture aims at understanding the materials based on silicates and their applications through analysis tools.

Course Objectives

This course deals with the optimization procedure for providing the solution of various engineering problems. The course includes a design of experiments, various surrogate models, single- and multi-objective numerical optimizations and practical engineering applications using in-house code.

Course Objectives

This lecture aims at understanding the basic concept of thermo-chemical fuel conversion systems for various kinds of energy(heat and electricity) production system.

Course Objectives

This lecture aims at learning CO2 conversion technology using various active catalyst systems and understanding knowledgies about their structures and reactivities.

Course Objectives

This lecture aims at understanding thermo-chemical conversion methods of low rank fuels. Pyrolysis, gasification, and combustion of solid and liquid fuels will be discussed.

Course Objectives

This course deals with the numerical simulation of fluid flow and heat transfer. The course includes an introduction to numerical methods, FDM & FVM, turbulence modeling and practical application of commercial CFD code. The optimized numerical design methods combined with DOE are also important subjects.

Course Objectives

This lecture aims at understanding the basic concept of their major through the introduction of 'Green Process and System Engineering.

Course Objectives

This course deals with an introduction to the broad diversity of turbomachinery including pumps, compressors and turbines. The course includes coverage of basic physical understanding of the design and performance of turbomachines. The design process of impeller and other components of pumps and compressors are also important subjects.

Course Objectives

Green bioenergy engineering aim at overall basic understanding of biomass and organic biowaste derived biofuel and bioenergy.

It covers biocrop and biowaste feedstock preparation, bio-thermo-chemical production of biogas, biohydrogen, biofuel such as bioethanol and biodiesel and thermal regeneration in forms of heat, steam and electricity along with renewable energy energy mix and future biofuels for ship and airplane.

Course Objectives

Green biobased chemical engineering aims at overall basic understanding of natural biomass resource derived conversion and production of biobased chemical materials. It covers from biomass raw material preprocessing up to biobased platform chemicals and macromolecules such as bioplastics along with terminology, bio-thermo-chemical conversion and purification.

Course Objectives

This lecture aims at learning basic techniques in synthesis, applications, physical structures and properties of polymers.

Details

Position

Head Professor

Major

Industrial Technology

Affiliation

UST-KITECH School

Division

Gren and Sustainable Materials R&D Department

shshin@ust.ac.kr

Homepage

TEL

041-589-8422

Education

1992-02 / Seoul National University / Bachelor's

1994-02 / Seoul National University / Master's

1998-02 / Seoul National University / Doctor's

Representative Study

H.-W. Park, M. Toan, H.-J. Kim, J.H. Lee, S. Shin†, “Renewable epoxy thermosets with extremely high biomass content from furan derivatives and their flame retardancy”, J. Ind. Eng. Chem., 92, 184-190 (2020).

H.-W. Park, H.-S. Seo, J.H. Lee, S. Shin†, “Adhesion improvement of the acrylic pressure-sensitive adhesive to low-surface-energy substrates using silicone urethane dimethacrylates”, Eur. Polym. J., 137, 1009949 (2020).

T. Nguyen, Y.J. Kim, S.-K. Park, K.-Y. Lee, J.-Y. Park, J.K. Cho, S. Shin†, “Furan-2,5- and Furan-2,3-dicarboxylate Esters Derived from Marine Biomass as Plasticizers for Poly(vinyl chloride)”, ACS Omega, 5, 197-206 (2020).

Performance

Thermal/photo-curable materials for automotive and electronic application

Polymer-based smart coating materials

Sustainable chemicals and polymers from renewable resources

Details

Position

Professor

Major

Industrial Technology

Affiliation

UST-KITECH School

Division

Gren and Sustainable Materials R&D Department

inpark@kitech.re.kr

Homepage

TEL

041-589-8225

Education

1998-02 / Yonsei University / Bachelor's

2000-02 / Seoul National University / Master's

2006-05 / Michigan State Univ / Doctor's

Representative Study

Facile Fabrication of Transparent Superhydrophobic Surfaces by Spray-Deposition / ACS Appl. Mater. Interf. / 2011.07.27

Fabrication of raspberry-like superhydrophobic hollow silica particles / Mater. Letters / 2010.10.31

Water adsorption capacity enhancement of ferroaluminophosphate (FAPO4-5) by impregnation of CaCl2 / Mater. Letters / 2018.06.21

Performance

Development of artificial skin using nano-catalyst for improved anti-wrinkle

Cost-effective Chemical Process for Organosilicon Polymers with High Durability

Green Slippery Packaging Development

Development, Standardization and Field Test of High Energy-Efficient Freezer/Refrigerator System

Details

Position

Principal Researcher, Professor

Major

Green Process and Energy System Engineering

Affiliation

Research Institute of Sustainable Development Tech

Division

Industrial Energy R&D Department

yschoi@kitech.re.kr

Homepage

TEL

041-589-8337

Education

1988-02 / Seoul National University / Bachelor's

1990-02 / Seoul National University / Master's

1996-02 / Seoul National University / Doctor's

Representative Study

- Yong-In Kim, Sang-Yeol Lee, Hyeon-Mo Yang, Kyoung-Yong Lee, Sang-Ho Yang, and Young-Seok Choi, 2022, “Suppression of stall-induced instability and positive slope at low flow rates of an axial fan with two-dimensional anti-stall fin”, Journal of Fluids Engineering, 144(12)

- Yong-In Kim, Hyeon-Mo Yang, Kyoung-Yong Lee, and Young-Seok Choi, 2022, “Numerical investigation on blockage-related cavitation surge and pressure gain of a mixed-flow pump with influence of blade leading edge shape on suction performance”, Journal of Fluids Engineering, 144(9)

- Yong-In Kim, Hyeon-Mo Yang, Kyoung-Yong Lee, and Young-Seok Choi, 2022, “Numerical investigation on functional limitations of the anti-stall fin for an axial fan: One-factor analyses,” Scientific Reports, 12(1)

Performance

- Development of Platform Technology and Operation Management System for Design and Operating Condition Diagnosis of Fluid Machinery with Variable Devices Based on AI/ICT

- Development of Reversible Axial Fan for Forward Driving

- Development of design program for centrifugal and mixed-flow pump(Ns 150-1200)

Details

Position

Professor

Major

Industrial Technology

Affiliation

UST-KITECH School

Division

Clean Energy R&D Department

kwonok@kitech.re.kr

Homepage

TEL

041-589-8528

Education

2000-02 / Pukyong National University / Doctor's

Representative Study

Sang Woo Hong, Sang Hyeok Ahn, Oh Kyung Kwon, and Jae Dong Chung/Optimization of a fin-tube type adsorption chiller by design of experiment/International Journal of Refrigeration, Vol.49, pp.49~56/2015.01.05

Oh Kyung Kwon, Kyung Jin Bae and Cha Sik Park/Cooling characteristics of ground source heat pump with heat exchange methods/Renewable Energy Vol.71, pp.651~657/2014.07.04

Ohkyung Kwon, Dongan Cha, Chasik Park/Performance evaluation of a two-stage compression heat pump system for district heating using waste energy/Energy, Vol.57, pp.375~381/2013.08.06

Performance

Development of waste heat driven chilled water and steam generation absorption heat pump for industrial process

Development of low temperature waste driven low power adsorption cooling system

Development of a smart hybrid dryer and waste heat recovery type hot air flow

Details

Position

Professor

Major

Industrial Technology

Affiliation

UST-KITECH School

Division

Clean Energy R&D Department

yangwon@kitech.re.kr

Homepage

TEL

041-589-8265

Education

1995-02 / Korea Advanced Institute of Science and Technology / Bachelor's

1997-02 / Korea Advanced Institute of Science and Technology / Master's

2004-02 / Korea Advanced Institute of Science and Technology / Doctor's

Representative Study

Carbon capture technology through oxy-fuel combustion

Technologies on fuel substitution and clean combustion for reducing pollutant emissions and CO2 emission

Energy systems for renewable fuels (waste, biomass. etc)

Performance

Development of a smart management system for large-scale boilers purposed to reduction of CO2 emissions

Development of countmeasure technologies for operational problems in energy plants using variable fuels

Development of a high efficient, zero-emission boiler and a CO2 capture/purification technology for thermal power generation based on pressurized oxy-combustion

A Study on moisture re-absorption characteristics of dried coals

Establishement of a on-site test bed for technology demonstration based on a real-scale thermal power plant

Demonstration of biomass torrefaction system of high efficiency targeted to biomass upgrading for thermal power plant

Development of ultra low NOx combustion technology for coal thermal power plant

Details

Position

Professor

Major

Green Process and Energy System Engineering

Affiliation

KITECH

Division

Carbon Neutral Technology R&D Department

uendol@kitech.re.kr

Homepage

TEL

+82-41-59-8574

Education

1997 / KAIST Mechnical engineering / Bachelor's

1999 / KAIST Mechnical engineering / Master's

2005 / KAIST Mechnical engineering / Doctor's

Representative Study

“One-dimensional numerical simulation of CFB combustion: Improvement of hydrodynamic models for accurate prediction of pressure and particle size distributions,”C Yang, H Kwon, B Bang, S Kim, D Pallarès, B Leckner, U Lee, Fuel 346, 128315 / 2023

“One-dimensional kinetic model with heat transfer and axial dispersion of molten-metal bubble column reactors for hydrogen production via methane pyrolysis,”BT Le, SI Ngo, YI Lim, UD Lee, International Journal of Hydrogen Energy / 2023

“Methane pyrolysis rate measurement using electromagnetic levitation techniques for turquoise hydrogen production: Liquid In, Ga, Bi, Sn, and Cu as catalysts,” TG Wi, YJ Park, U Lee, YB Kang, Chemical Engineering Journal 460, 141558 / 2023

“Hydrodynamics of molten-metal bubble columns in the near-bubbling field using volume of fluid computational fluid dynamics,” SI Ngo, YI Lim, HM Kwon, UD Lee, Chemical Engineering Journal 454, 140073 / 2023

“Assessment of Greenhouse Gas Emissions from Hydrogen Production Processes: Turquoise Hydrogen vs. Steam Methane Reforming,” GU Ingale, HM Kwon, S Jeong, D Park, W Kim, B Bang, YI Lim, SW Kim, UD Lee, Energies 15 (22), 8679 / 2023

“Role of biomass as low-carbon energy source in the era of net zero emissions,” C Yang, H Kwon, B Bang, S Jeong, U Lee, Fuel 328, 125206 / 2023

“Numerical simulation method of a circulating fluidized bed reactor using a modified MP-PIC solver of OpenFOAM,” I Cho, C Yang, H Kwon, B Bang, S Jeong, U Lee, Powder Technology 409, 117815 /2022

Performance

Development of CO2-free hydrogen production process based on thermochemical conversion of C-X compounds using solar energy (2021-2026)

Development and commercialization for clean hydrogen production/storage and CO2 monitoring system in the field of industrial (2023-2027)

Development of combined cycle of magnetohydrodynamics(MHD) and hydrogen gas turbine with turquoise hydrogen (2022-2027)

Development of innovative plastic refinery technology for hydrogen and carbon production (2022-2027)

Development of turquoise H2 and C(s) production technology by methane cracking (2022-2024)

Development of technology for simultaneous treatment of multiple greenhouse gases based on liquid metal (2022-2024)

Development of 8 MWth class biomass gasification system and demonstration (2018-2022)

Details

Position

Principal Researcher

Major

Convergence Manufacturing System Engineering

Affiliation

Research Institute of Sustainable Development Tech

Division

Low-Carbon Conversion

yjkim@kitech.re.kr

Homepage

TEL

010-6381-5689

Education

1996-08 / Sogang University / Bachelor's

1999-08 / Sogang University / Master's

2003-08 / Sogang University / Doctor's

Representative Study

MnCo2O4 spinel supported ruthenium catalyst for air-oxidation of HMF to FDCA under aqueous phase and base-free conditions, Green Chemistry/2017

Molecularly engineered linear organic carbonates as practically viable nonflammable electrolytes for safe Li-ion batteries, Energy & Environmental Science/2023

Sustainable Catalytic Transformation of Biomass‐Derived 5‐Hydroxymethylfurfural to 2, 5‐Bis (hydroxymethyl)tetrahydrofuran, ChemSusChem/2022

Selenite-catalyzed oxidative carbonylation of alcohols to dialkyl carbonates, Applied Catalysis B: Environmental/2019

Performance

Synthetic Development of Lube Base Oil from C6 furan compounds(2020~2025)

Technology for [C1+C5]-based Core Material(2017~2019)

Synthesis of CO2-Marine Biomass based Platform Chemical and Functionalization of Eco-polymer(2012~2016)

Details

Position

Associate Professor

Major

Industrial Technology

Affiliation

UST-KITECH School

Division

Clean Energy R&D Department

jinhyuk@kitech.re.kr

Homepage

TEL

041-589-8447

Education

2013-08 / Inha University / Doctor's

Representative Study

Mohamed Murshid Shamsuddeen, Jungwan Park, Young-Seok Choi and Jin-Hyuk Kim, "Unsteady Multi-Phase Cavitation Analysis on the Effect of Anti-Cavity Fin Installed on a Kaplan Turbine Runner," Renewable Energy, Vol. 162, December 2020, pp. 861-876.

Arihant Sonawat, Young-Seok Choi, Kyung Min Kim and Jin-Hyuk Kim, "Parametric Study on the Sensitivity and Influence of Axial and Radial Clearance on the Performance of a Positive Displacement Hydraulic Turbine," Energy, Vol. 201, 15 June 2020, Paper No. 117587.

Arihant Sonawat, Seung-Jun Kim, Hyeon-Mo Yang, Young-Seok Choi, Kyung Min Kim, Yong-Kab Lee and Jin-Hyuk Kim, "Positive Displacement Turbine - A Novel Solution to the Pressure Differential Control Valve Failure Problem and Energy Utilization," Energy, Vol. 190, 1 January 2020, Paper No. 116400.

Performance

[Asia] The Enhanced Performance Development of Ultra Small Hydraulic Power Generator Utilizing State-of-the-art Techniques based on Machine Learning

Shape and CFD Performance Analyses of a Multi-Stage Centrifugal Pump

A Study on the Small Hydropower Generation Technology with the Unused Energy of the Cooling Tower in 500MW Class Cogeneration Power Plant

Serialized Development on Cost Saving 2 Vane Pump for Transferring Solid Matter

Development of Construction Technology for Medium Sized Hydropower Plant

Details

Position

Principal researcher/Managing directer

Major

Green Process and Energy System Engineering

Affiliation

Seonam Division

Division

Seonam Division

chjeong@kitech.re.kr

Homepage

TEL

+82-10-5872-7770

Education

2000 / Chonnam National University Department of Inorganic Materials Science and Engineering/ Bachelor's

2002 / Chonnam National University Department of Inorganic Materials Science and Engineering/ Master's

2008 / Tokyo University of Agriculture and Technology, Electronics Science and Engineering / Doctor's

Representative Study

1. Efficient thin crystalline silicon photoanode with lithium fluoride based electron contacts, Thin Solid Films / 2023

2. Flexible transparent photovoltaics for ultra-UV photodetection and functional UV-shielding based on Ga2O3/Cu2O heterojunction, APPLIED MATERIALS TODAY/2022

3. Characteristics and Electronic Band Alignment of a Transparent p-CuI/n-SiZnSnO Heterojunction Diode with a High Rectification Ratio, Nanomaterials/2021

4. BF Boosting Solar Cell Performance via Centrally Localized Ag in Solution-Processed Cu(In,Ga)(S,Se)2 Thin Film Solar Cells, ACS APPLIED MATERIALS & INTERFACES/2020

5. Design of a solar cell electrode for a shingled photovoltaic module application, APPLIED SURFACE SCIENCE/2019

Performance

1. Development of core technologies of AI based self-power generation and charging for next-generation mobility/Project Director/2023~2027

2. Development of core materials for building integrated photovoltaic modules with long-term reliability (over 25 years) and safety/Project Director/2020~2024

3. Development of core technologies to strengthen competitiveness of both-sided modules/Project Director/2020~2024

4. Development & Field demonstration of PV modules for soundproofing facilities with secured safety and maintainability/Project Director/2020~2024

5. Development of Materials, Equipment, and Process Technology for Large-Scale Crystalline/Thin-Film Silicon Heterojunction (HJT) Photovoltaic Modules/Project Director/2020~2024

6. Building materials integrated built-in high efficiency PVT model development/Project Director/2021~2022

7.Development of steel integrated photovoltaic module for building application/Project Director/2019~2023

8.Development of high efficiency advanced PERC PV module/Project Director/2017~2020

9.Development of daily-life oriented power sources by using flexible CIGS thin-film solar cells/Project Director/2016~2019

10. Development of cell-to cell bonding technology for low cost and high efficiency photovoltaic module/Project Director/2016~2019

Details

Position

Principal Researcher

Major

Convergence Manufacturing System Engineering

Affiliation

Research Institute of Adbanced Manufacturing&Mater

Division

Industrial Materials Processing R&D Department

bonghk75@kitech.re.kr

Homepage

TEL

010-4242-1910

Education

1998 / Yonsei University / Bachelor's of Metallurgical Engineering

2000 / Yonsei University / Master's of Metallurgical Engineering

2021 / Yonsei University / Doctor's of Materials Science and Engineering

Representative Study

Effect of Ca addition on selective oxidation of Al3Mg2 phase in Al-5mass&Mg alloy (Paper) / 2018

Role of Ca in hot compression behavior and microstructural stability of AlMg5 alloy during homogenization (Paper) / 2020

Aluminum alloy with additions of magnesium, calcium and at least one of chromium, manganese and zirconium, and method of manufacturing the same (Patent) / 2018

Performance

Development of High-Strength and High Formability of 5000 and 6000 series Aluminum Alloy Sheets Fabricated by Low Cost Process / 2017-2023

Details

Position

Professor

Major

Green Process and Energy System Engineering

Affiliation

KITECH

Division

Carbon Neutral Technology R&D Department

jglee@kitech.re.kr

Homepage

TEL

0415898330

Education

2008 / Hanyang University / Bachelor's

2010 / Hanyang University / Master's

2015 / Hanyang University / Doctor's

Representative Study

․Evaluating the potential of superhydrophobic nanoporous alumina membranes for direct contact membrane distillation, Journal of Colloid and Interface Science 533, 723-732, 2019

․Multi-stage air gap membrane distillation reversal for hot impaired quality water treatment: concept and simulation study, Desalination 450, 1-11, 2019

․Direct contact membrane distillation module scale-up calculations: Choosing between convective and conjugate approaches, Separation and Purification Technology 209, 279-292, 2019

․Effect of seawater-coolant feed arrangement in a waste heat driven multi-stage vacuum membrane distillation system, Separation and Purification Technology 212, 12-20, 2019

․Predicting the performance of large-scale forward osmosis module using spatial variation model: Effect of operating parameters including temperature, Desalination 469, 114095, 2019

․Enhanced ammonia recovery from wastewater by Nafion membrane with highly porous honeycomb nanostructure and its mechanism in membrane distillation, Journal of Membrane Science 590, 117265, 2019

․Membrane distillation hybrids for water production and energy efficiency enhancement: A critical review, Applied Energy 254, 113698, 2019

․Numerical study of desalination by vacuum membrane distillation–Transient three-dimensional analysis, Journal of Membrane Science 596, 117609, 2020

․Performance investigation of a two-bed type adsorption chiller with various adsorbents, Energies 13 (10), 2553, 2020

․Effective membrane backwash with carbon dioxide under severe fouling and operation conditions, Journal of Membrane Science 611, 118290, 2020

․Integration of multi effect evaporation and membrane distillation desalination processes for enhanced performance and recovery ratios, Desalination 493, 114619, 2020

․Towards sustainable circular brine reclamation using seawater reverse osmosis, membrane distillation and forward osmosis hybrids: An experimental investigation, Journal of Environmental Management 293, 112836, 2021

․Experimental investigation of the solid desiccant dehumidification system with metal organic frameworks, International Journal of Refrigeration 130, 179-186, 2021

․Colloidal silica fouling mechanism in direct-contact membrane distillation, Desalination 527, 115554, 2022

․Desalination at ambient temperature and pressure by a novel class of biporous anisotropic membrane, Scientific Reports 12 (1), 13564, 2022

․Effect of fabrication technique on membrane distillation performance of photothermal membrane: Electrospinning vs electrospraying, Desalination 564, 116799, 2023

Performance

Development of hybrid adsorption chiller using unutilized heat source of low temperature

Development of an ultra-high efficiency heat pump system that reduces latent and sensible heat loads

Development of ultra low temperature cooling system for semiconductor etching process with cooling capacity of 2 kW

Hybrid heat pump Fluidized dryer in EV batteries recycling process for a water content of valuable metal under 1.5%

Development of vapor-liquid phase equilibrium measurement equipment for cryogenic mixed refrigerant

Details

Position

Major

Green Process and Energy System Engineering

Affiliation

KITECH

Division

Carbon Neutral Technology R&D Department

ks2928@kitech.re.kr

Homepage

TEL

0415898446

Education

2019 / HANYANG UNIVERSITY / Doctor's

Representative Study

METHOD OF DESIGNING CENTRIFUGAL AND MIXED FLOW PUMPS HAVING SPECIFIC SPEED OF 150 TO 1200 (10,474,787, USA, 2019)

Three-Objective Optimization of a Mixed-flow Pump Impeller for Improved Suction Performance and Efficiency (Advances in Mechanical Engineering, 2019)

Design Optimization for Mixed-flow Pump Impeller by Improved Suction Performance and Efficiency with Variables of Specific Speeds (JOURNAL OF MECHANICAL SCIENCE AND TECHNOLOGY,2020)

Performance

Development of industrial heat exchanger cleaning system and automatic operation technology for Maintaining an average annual energy savings of 25% or more based on carbon emissions

Development of inside solutions module to reduce harmful environmental factors in the atmosphere

Development of High Efficiency Hydro Power System for Flexible Operations in response to Partial Load

Details

Position

Principal Researcher

Major

Convergence Manufacturing System Engineering Green

Affiliation

Research Institute of Sustainable Development Tech

Division

Industrial Energy R&D Department

cklee@kitech.re.kr

Homepage

TEL

0415898275

Education

2009 / Korea Advanced Institute of Science and Technology (KAIST) / Bachelor's

2011 / Korea Advanced Institute of Science and Technology (KAIST) / Master's

2017 / Korea Advanced Institute of Science and Technology (KAIST) / Doctor's

Representative Study

(Paper)

Experimental investigation on a non-flammable mixed refrigerant Joule-Thomson refrigerator for a 100 K cooling temperature, Applied Thermal Engineering / 2024

Experimental Investigation of 2kW Class Non-flammable Mixed Refrigerant Joule-Thomson Refrigerator with Cooling Temperature of -100 °C for Cryogenic Etching / Journal of the Semiconductor & Display Technology / 2023

Measurement of Condensation and Boiling Heat Transfer Coefficients of Non-flammable Mixed Refrigerant for Design of Cryogenic Cooling System for Semiconductor Etching Process / Journal of the Semiconductor & Display Technology / 2023

(Technical asset)

80℃ class ultra-low temperature chiller miniaturization technology for semiconductor process / 2024

Two-stage cascade cycle design technology in the form of mixed refrigerant based on -80℃ cooling temperature and 6 kW cooling capacity for semiconductor processing / 2023

2 types of vapor compression cycle simulation and analysis results in the form of mixed refrigerant based on -40℃ cooling temperature and 8 kW cooling capacity for semiconductor processing / 2022

Performance

Development of cryocooler and liquefaction system for on-site production of liquid nitrogen (KEIT, 2024.04 – 2027.12)

Development of High-Efficiency Ultra-Low Temperature Refrigeration Equipment for –100℃ Using Natural Refrigerants (KETEP, 2024.04 – 2028.03)

Development of a chemical supply box that reduces usage more than 50% based on chemical reuse (KEIT, 2023.07 – 2026.12)

Development of ultra low temperature cooling system for semiconductor etching process with cooling capacity of 2 kW (KEIT, 2021.04 – 2024.12)

Development of environmental friendly cascade chiller cooling temperature of ?40℃ for semiconductor manufacturing process (UNISEM, 2023.05 – 2024.12)

Details

Position

Professor Emeritus

Major

Green Process and Energy System Engineering

Affiliation

UST-KITECH SCHOOL

Division

sykim@ust.ac.kr

Homepage

TEL

+82-10-6266-3865

Education

1982 / Seoul National University / Bachelor's degree in Chemical Engineering

1990 / Tulsa University / Master's degree in Chemical Engineering

1994 / New Mexico State University / Doctor's degree in Chemical Engineering

Representative Study

*Corynebacterium Cell Factory Design and Culture Process Optimization for Muconic Acid Biosynthesis(Scientific Reports)/2018

*Techno-economic assessment of hybrid extraction and distillation processes for furfural production from lignocellulosic biomass(Biotechnology for Biofuels)/2017

Design and optimization of intensified biorefinery process for furfural production through a systematic procedure(Industrial & Engineering Chemistry Research)/2016

Performance

*Development of bio-PTT polymer for textile & engineering plastics(2013~2017)

*Development of Itaconic acid derived furanic materials for advanced biofuels and bio-monomers(2014~2015)

*Process development of biobased C3~C6 platform chemicals(2011~2013)

Details

Position

Principal Researcher

Major

Green Process and Energy System Engineering

Affiliation

Research Institute of Sustainable Development Tech

Division

Low Carbon Transition R&D Department

jbaek@kitech.re.kr

Homepage

https://scholar.google.com/citations?user=FA7rwSsAAAAJ&hl=en

TEL

041-589-8358

Education

2009 / Ewha Womans University / Bachelor's

2015 / Seoul National University / Doctor's

Representative Study

J. Lee†, A-R. Jeon†, H. J. Lee, U. Shin, Y. Yoo, H. -D. Lim, C. Han, H. Lee, Y. J. Kim, J. Baek*, D. -H. Seo*, M. Lee*,“Molecularly engineered linear organic carbonates as practically viable nonflammable electrolytes for safe Li-ion batteries”Energy Environ. Sci., 16, 2924-2933 (2023).

A. V. Tran†, S. -K. Park†, H. J. Lee, T. Y. Kim, Y. Kim, Y. -W. Suh, K. -Y. Lee, Y. J. Kim*, J. Baek*,“Efficient production of adipic acid by a two‐step catalytic reaction of biomass‐derived 2, 5‐furandicarboxylic acid”ChemSusChem, 15, e202200375 (2022).

J. Baek†, B. Rungtaweevoranit†, X. Pei, M. Park, S. C Fakra, Y.-S. Liu, R. Matheu, S. A. Alshmimri, S. Alshehri, C. A Trickett, G. A Somorjai*, O. M. Yaghi*,“Bioinspired metal–organic framework catalysts for selective methane oxidation to methanol”J. Am. Chem. Soc., 140, 18208-18216 (2018).

B. Rungtaweevoranit†, J. Baek†, J. R Araujo, B. S Archanjo, K. M. Choi, O. M Yaghi*, G. A Somorjai*, “Copper nanocrystals encapsulated in Zr-based metal–organic frameworks for highly selective CO2 hydrogenation to methanol”Nano Lett., 16, 7645-7649 (2016).

Performance

Developing the commercialization technology of the biodegradable polybutylene plastics PBAT and PBS from biomass (MOTIE, 2022-2025)

Synthetic Development of Lube Base Oil from C6 furan compounds (MSIT, 2020-2025)

Predevelopment of flame retardant electrolyte for lithium ion battery (MSIT, 2021-2022)

Development of catalyst and process for synthesis of green plastic polymer resin and monomer from biomass (MSIT, 2020-2024)

Details

Position

Principal Researcher

Major

Green Process and Energy System Engineering

Affiliation

UST-KITECH SCHOOL

Division

Clean Energy Transition Group

jeonghoon@kitech.re.kr

Homepage

TEL

064-754-1536

Education

2010 / Hanbat National University / Bachelor's

2012 / Korea University / Master's

2016 / Korea University / Doctor's

2016-2018 / Korea University / Research Professor

2018-2019 / Northwestern University / Post-doctoral Researcher

Representative Study

Since 2019

[Papers] Inhibiting bacterial biofilm formation by stimulating c-di-GMP regulation using citrus peel extract from Jeju Island, Science of the Total Environment and 50 other publications

[Book] Current Developments in Biotechnology and Bioengineering 1st Edition (Strategic Perspectives in Solid Waste and Wastewater Management). Ch. 5. Advanced Wastewater Treatment Technologies, Elsevier

Performance

Since 2023 (as a PI)

1. Mixed strain improvement and continuous production system development for commercialization of carbon-neutral biohydrogen derived from organic waste (Grant No. NRF-2022M3I3A1082540: 07/01/2022 – 12/31/2026), Sponsored by the Korea National Research Foundation

2. Isolation of Probiotic Yeast Originated from Jeju and Development of Large-Scale Production Process for (Grant No. 08/01/2023 – 12/31/2024)”, Sponsored by the Ministry of Trade, Industry and Energy(MOTIE, Korea)

3. Commercialization Development of Jeju-derived food fermentation yeast and production of Jeju specialized premium food and beverages (Grant No. S3371529: 06/01/2023 – 12/31/2024)”, Sponsored by the Korea Technology and Information Promotion Agency for SMEs(TIPA)

4. Comprehensive Study on the Identification of Superior Microbial Strains and the Development of Formulations for Enhanced Food Waste Disposal (Grant. No. PJB240013: 01/01/2024 – 12/31/2025), Sponsored by the Korea Institute of Industrial Technology

Gas chromatography

Holding Area

Ulsan

Equipment Description

휘발성 시료를 구성한 물질이 얼마나 있는지를 규명하는데 사용되는 보편화된 장비로 단일화합물이 컬럼을 빠져나온 시간과 검출기 감응에 대한 면적을 통해 정성 정량 분석이 가능한 장치

Specific surface area measuring instrument

Holding Area

Ulsan

Equipment Description

Powder Pellet Core 등의 형태를 가지는 시료를 전처리 공정을 통해 불순물 및 유해 가스를 제거한 후 질소 등의 가스를 주입하여 화학적 흡탈착 현상으로부터 Meso/Micro porous 영역의 다공성 물질의 Specific Surface Area Pore Size Pore Volume 등을 측정하는 장비

Multiple gas detectors

Holding Area

Cheonan

Equipment Description

Universal material testing machine

Holding Area

Cheonan

Equipment Description

각종재료의 인장강도시험이 가능하며 별도의 지그를 사용한 기타 시험도 가능한 만능시험기. AC Servo Motor 에 의한 정밀한 시험속도의 제어가 속도스위치 및 CPU system 으로 간단히 변환되며 고정도의 로드셀에 의해 시료에 가해지는 하중을 정밀하게 되는 Interface board 를 통하여 CPU System에서 수집, 분석된다. 또한 시료의 신장량의 측정을 Rotary Encorder 로서 측정하여 이 또한 디지탈로 표시함으로서 일반적인 인장강도시험을 정밀하고 간단하게 시험할 수 있게 한다.

High speed performance liquid chromatography

Holding Area

Cheonan

Equipment Description

X-ray diffraction analyzer

Holding Area

Cheonan

Equipment Description

재료의 결정면에 X-선을 주사하여 일어나는 회절현상을 이용하여 물질의 결정구조를 분석하는 장비. XRD는 회절된 X-ray 감도들에 의해서 변화들이 시료의 회절각에 의해서 회절되고, 기록되며, 측정되어진다. 이 결과로 시료의 X-ray 회절 패턴을 알 수 있다. 피크 위치와 감도들은 컴퓨터 분석을 통하여 정성분석과 격자 상수 결정 그리고 시료의 stress 결정을 할 수 있도록 도와준다. 피크의 각도와 윤곽들은 입자사이즈를 결정하는데 사용되며, 결정화도를 결정하는데도 이용된다.

Polymer synthesis reactor

Holding Area

Cheonan

Equipment Description

이산화탄소 기반 플랫폼 화합물 제조기술 관련 고분자 제조를 위해 필요한 반응기 시스템. 화합물을 합성할 때 반응조건을 조절하기 위해 교반속도, 온도 등을 조절한다.

Polymer viscoelastic thermal analyzer

Holding Area

Cheonan

Equipment Description

천연재생자원인 바이오매스를 이용하여 열/기계적 물성이 우수하여 전기전자 소재/부품용으로 사용이 가능한 바이오고분자 소재의 상용화 생산공정의 개발을 위한 실험에 있어, 개발된 고분자 소재의 점탄성 분석을 통한 고분자의 물리화학적 구조 및 기계적 성질을 측정/분석하는 장비

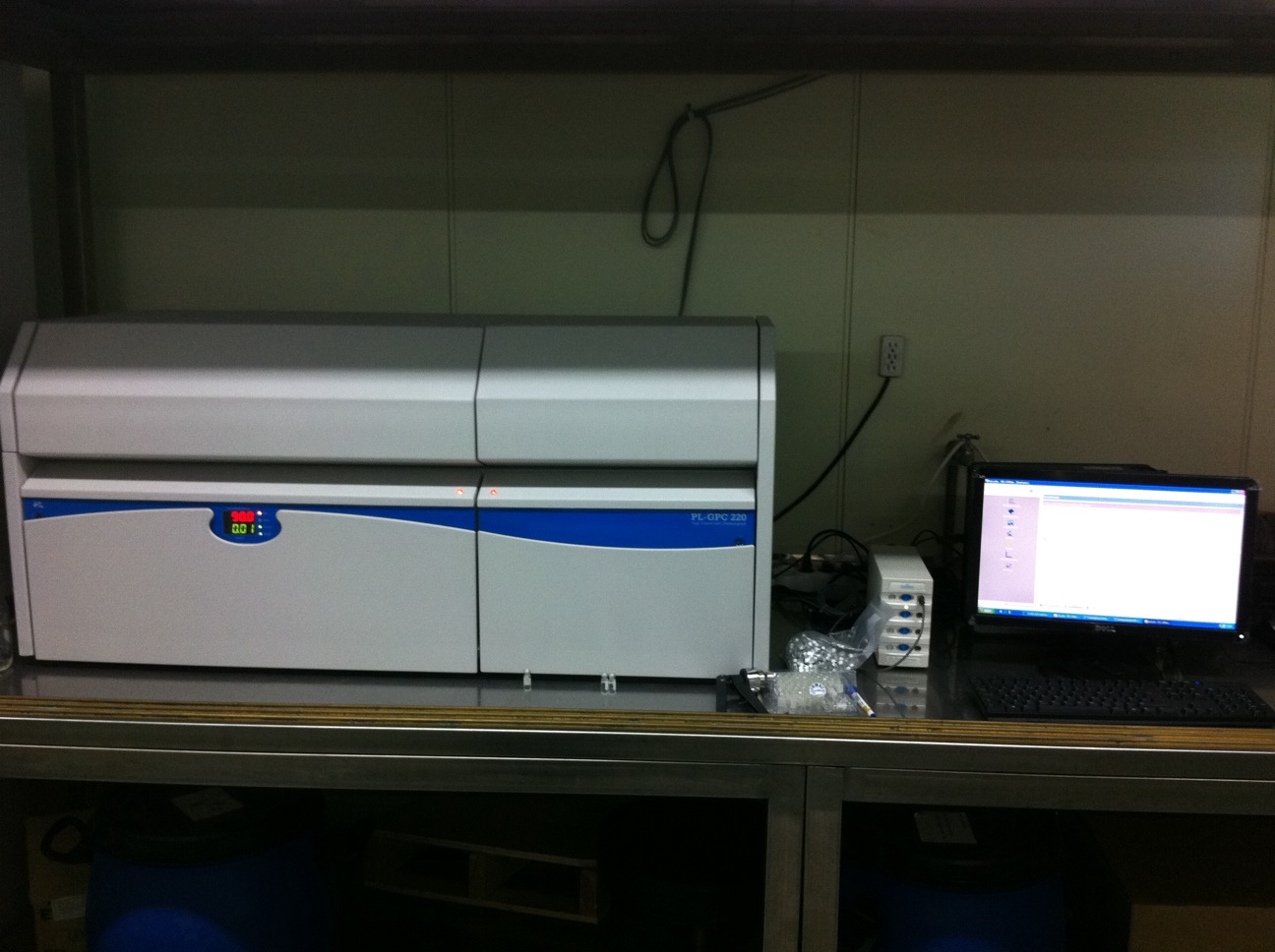

High temperature GPC (Gel permation chloromatograp

Holding Area

Cheonan

Equipment Description

Differential scanning calorimetry

Holding Area

Cheonan

Equipment Description

'There is no such information.'